User Creates Plan

A load plan is created with a specific number of cartons (e.g., 652 packages).

The Solver generates optimal load plans in the background after shipment data is published. The Solver strictly follows user-provided carton counts, which can sometimes leave underutilized space due to The 68 CBM mindset. The Advisor intelligently identifies and fills empty space, revealing the true potential of every shipment. It suggests the additional quantities that users might have initially overlooked.

For years, a common perception has limited the efficiency of container shipments: the belief that high-cube containers cannot be filled beyond approximately 68 Cubic Meters (CBM). This mindset often leads to deliberately conservative input quantities during load planning.

The consequence is significant: valuable container space remains unused, translating directly into wasted shipping costs and missed opportunities for maximizing freight efficiency. This deliberate under-utilization stems from historical manual planning limitations and a cautious approach to avoid overstuffing.

Limited Inputs

User inputs are capped below true container potential.

Wasted Space & Cost

Paying for empty air in every shipment.

To address the challenge of underutilized space, we developed the LoadViewer Advisor. This intelligent, proactive feature goes beyond simply optimizing given inputs; it actively identifies and suggests additional quantities to fill every available cubic meter, ensuring you get the most out of your freight spend.

The Advisor empowers you to break the 68 CBM barrier and unlock the true, often underestimated, potential of your containers. Once you visualize the Advisor's outcome, you'll definitely break The 68 CBM mindset – after all, everyone enjoys seeing a tree laden with fruits rather than a tree with more leaves than fruits! It represents a significant leap forward in maximizing your shipping efficiency and demonstrating greater value.

Financial Savings

Significantly reduce per-unit shipping costs by maximizing container utilization.

Operational Efficiency

Achieve more with fewer shipments, streamlining your logistics.

Environmental Impact

Reduce your carbon footprint by optimizing space and minimizing empty runs.

Strategic Advantage

Gain a competitive edge through smarter, more cost-effective shipping.

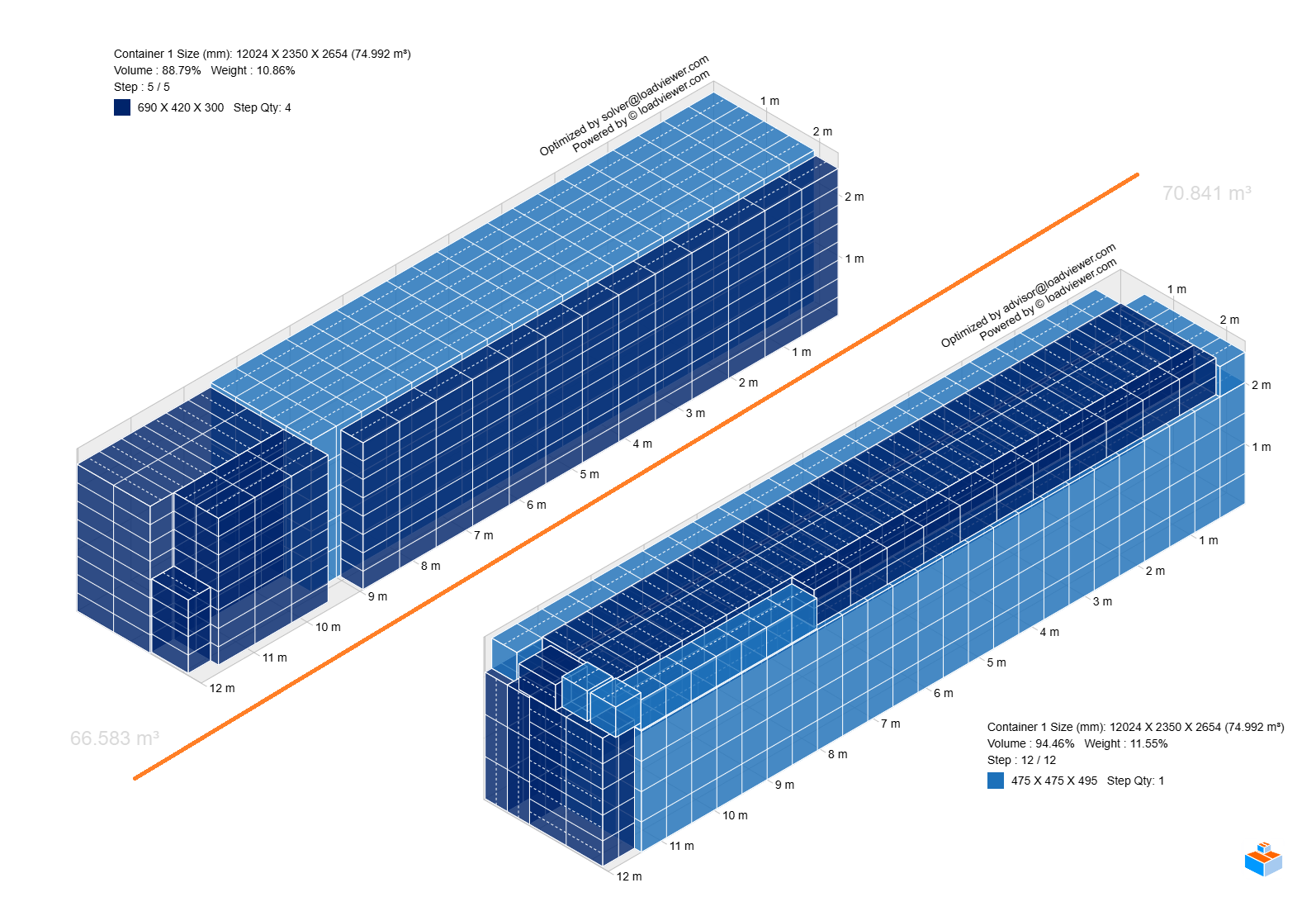

Let's look at a recent example where the Advisor demonstrated its power. A user planned a shipment with two carton types, with varying number of cartons, believing the container was full with 66.583 CBM. The Solver optimized this plan. Simultaneously, the Advisor analyzed the same shipment to find opportunities for improvement.

Container Capacity:

74.99 m³ / 28,600 kg

User-Provided Cartons:

652 Packages

Solver

88.79%

Volume : 66.583 m³

Advisor

94.46%

Volume : 70.841 m³

The Advisor's plan achieved significantly higher volume utilization by optimizing the available container space. Let's break down how.

The difference between the two plans represents a tangible loss in efficiency and a missed opportunity for cost savings. The Advisor successfully identified space to add 43 more packages.

+43

Additional Packages

4.258 m³

Additional Volume

+5.67%

Volume Utilization Gain

Rs. 10,645

LCL Cost Saved

1 Hi-Cube

Saved after Every 16

1 TEU

Saved after Every 8

1,066 kg of CO2

Emissions reduced every 8 TEUs

42.64 Trees

Lesser Required every 8 TEUs

The Advisor strategically added more of both carton types to the load plan, demonstrating that more capacity was available than initially assumed.

Download Solvers's Plan (159 kb) Download Advisor's Plan (171 kb)

A load plan is created with a specific number of cartons (e.g., 652 packages).

The Solver optimizes the user's plan. Simultaneously, the Advisor re-evaluates for hidden capacity.

Compare the two reports. The Advisor's higher score highlights an opportunity.

Adopt the Advisor's suggested plan, increasing efficiency and reducing per-unit cost. Otherwise, if there is no possibility of quantity revisions in the current shipment, you can use the Advisor's insights to revise similar future orders.

Start using LoadViewer today and uncover the true potential of your containers.

If you have any questions or need assistance, our support team is here to help. Feel free to reach out to us at support@loadviewer.com.