Your Guide to Smarter Shipments

Getting Started: Your First Free Demo

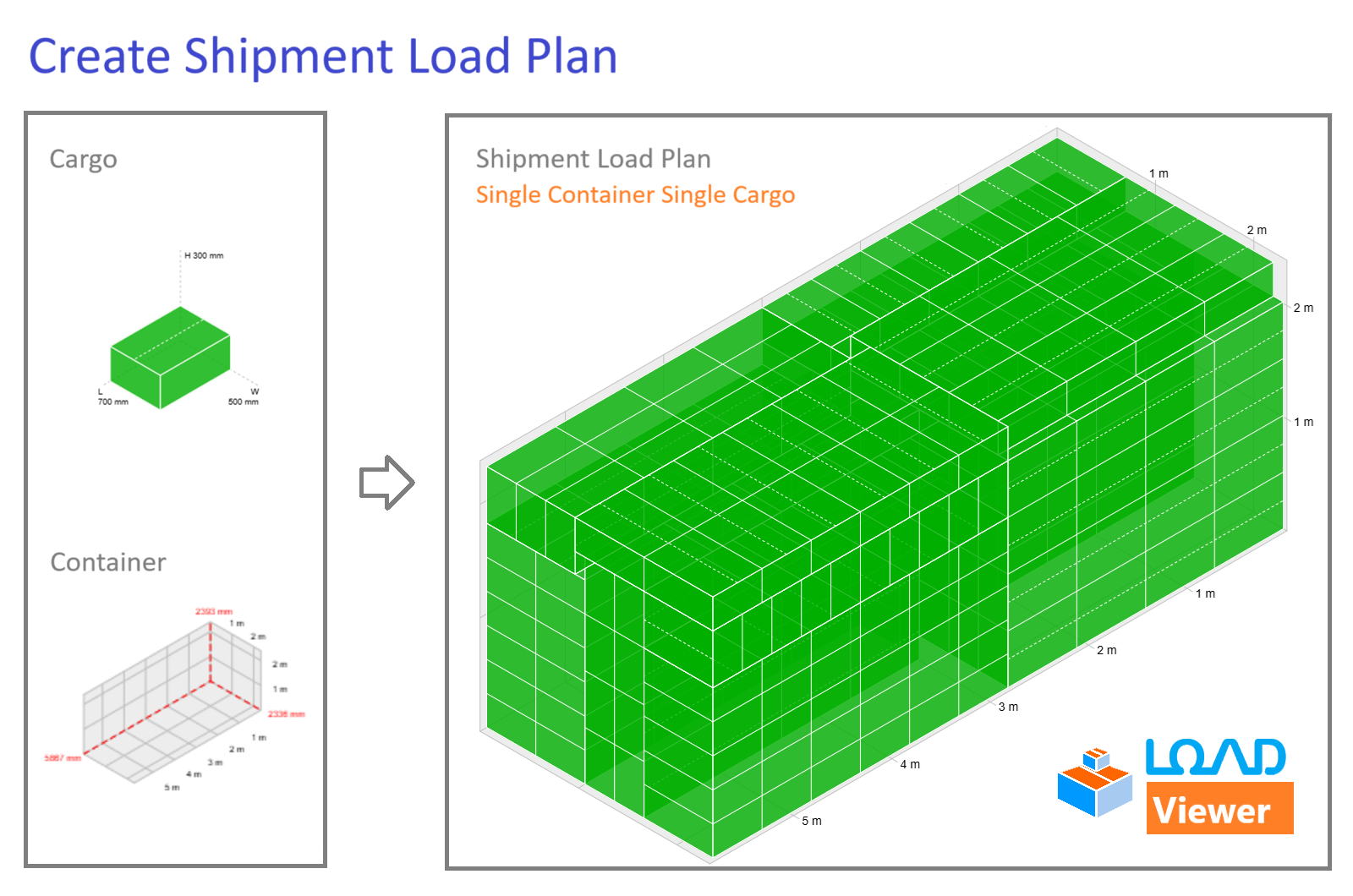

This guide walks you through the free demonstration of LoadViewer. The demo is designed for a single-container, single-cargo shipment to give you a feel for how our load planning algorithm works.

Need help? Click the button on the create shipment screen to start an interactive tour of all the fields.

Your Load Plan, Step-by-Step

The demo is a simple, three-part process that requires no sign-up: define your container, add your cargo, and create your single container, single cargo load plan. To explore more complex load plans, a full sign-up is required.

General Section

- Imperial Units: Check this box to display conversions in imperial units. All your inputs must still be in metric.

Shipment Section

- Shipment Reference: Enter a unique reference number.

Container Section

Start by defining the physical dimensions and weight capacity of your container. The inputs are in millimeters and kilograms.

- Container Type: Select from a list of standard types to quickly populate the dimensions.

- Length, Width, Height: Enter the internal dimensions of your container.

- Maximum Weight: Define the total weight your container can hold.

Cargo Section

Next, define the items you want to pack inside the container.

- Length, Width, Height: Enter the dimensions of a single carton.

- Weight: Enter the weight of a single carton.

- Vertical Rotation: Check this box to allow the system to vertically rotate your cargo for a more efficient fit.

- Color: Select a color to identify your cargo in the 3D visualization.

- Cartons to Pack: Enter the total number of cartons you need to pack.

Create Shipment

After you have filled in the required fields, click the Create button. For demo users, your shipment will be created and immediately published. The optimized load plan will be sent directly to your email address, allowing you to try our product risk-free. LoadViewer uses a background process to generate load plans so that you can utilize your time to do other important tasks instead of waiting for the plan to appear on screen.

Advanced Options

Each section has advanced options to give you more control over your load plan.

This section allows you to define more complex shipment details to support multi-step logistics and specific handling requirements.

- Fill Extra Cargo: If your cargo quantity fits within the capacity of a single container, and if you check this box, the system will suggest additional quantities of your cargo to fill the container to its maximum space utilization, answering the question, "How many quantities would fit in?"

- Allow Overhang: This option should be checked if you want your stacked cartons to hang in the air with a minimum of 75% base support. Uncheck this option to get 100% base support for your stacked cartons.

- Keep Orders Together: Use this checkbox to ensure that all items from a single purchase order are packed into the same container. This prevents an order from being split across multiple containers, simplifying inventory management and unloading.

- Mandatory Cargo Id: This option enforces a rule that an ERP ID must be included in the load plan, ensuring it is synced correctly with your ERP. If supplied, this ID will be sent back to your ERP to trigger actions like order revisions.

This section allows you to define technical specifications that impact how your container is loaded. You can control:

- Door Latch Margin: Define the empty space to be reserved near the container doors to allow for latches and other fixtures. This ensures your load plan is physically accurate.

- Refrigerated Container: Check this box if the container is refrigerated. The algorithm will account for any internal equipment and space constraints required for refrigerated cargo.

- Single-Use Container: Indicate if a container should be used only once. The LoadViewer algorithm will not plan more than one instance of this container type, even in a multi-container shipment.

- LCL CBM: Use this field to define the cubic meter (CBM) threshold below which it is more economical to ship via LCL (Less than Container Load) rather than FCL (Full Container Load). The Sensible Loading feature will use this threshold to evenly distribute cargo among all containers, creating simpler load plans.

This section provides powerful controls to customize how your cargo is packed, accommodating any handling constraints.

- Pallet Height: Define the height of an empty pallet. This value is added to the cargo's height for a more accurate volume calculation.

- Top Cap / Bottom Tray: Specify the height of protective caps (like corrugated cardboard) on the top or bottom of your cartons. These don't increase the overall volume but ensure proper spacing and protection.

- Perceived Deviations: Accommodate for slight imperfections in your cartons' dimensions. Define margin values for length, width, and height to account for any bulges or inaccuracies, ensuring a more realistic and reliable load plan.

-

Destination (LIFO): Define a destination for each item. The system uses a **Last-In, First-Out (LIFO)** rule to generate a plan that avoids unnecessary handling and movement of goods. This is crucial for:

- Multi-Stop Routes: The cargo for the last stop is loaded first, so items can be easily unloaded in sequence at each destination.

- Multiple Loading Departments: Items from the same department are grouped together, preventing them from being shuffled around and making the loading process more efficient.

- Items per Carton / SKU: For your inventory records, define the number of individual items or Stock Keeping Units (SKUs) contained within each carton.

- PO Number & Shipper: Identify the Purchase Order and the Shipper (loading bay) for each item. This allows your team to easily sort and load cargo from specific locations.

- Proportionate Packing: Use a Set Name and Set Quantity to ensure certain cartons are packed together in specific ratios. This is useful for kits or multi-part orders.

Want to check LoadViewer efficacy!

Want to find out how much LoadViewer can save for you? Conduct a quick litmus test! Simply send us your packing list in PDF, image, or CSV format along with any specific placement constraints for your Cargo.

Email your packing list and CBM value to solver@loadviewer.com, and we'll provide you with a detailed analysis with 3d visualization of container loading steps.

Create your first shipment online